The Army was but one of a series of handguns

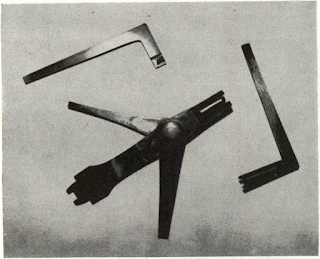

The creeping lever was designed by Elisha Root in

The lever as fitted to the Army had six studs which

pressed hard into the steel barrel and sometimes raised

The Army weighing two pounds 11 ounces was

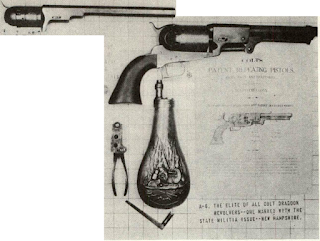

Some time late in or early Colt had several experimental Dragoon revolvers made up. Their

subject of his biography, General Wade Hampton,

According to Glenn E. Davis, quoted in Butler And

The Navy frame from the .36 belt pistol was selected

This pistol was marked “M” on barrel, frame, and

On pistol “M,” Nos. 37, and 78, the small Navy

Colt’s endorsement on this letter set factory policy

The long handle frame appears to have been pioneered on the hinged lever New Model pistols; at least,

The Dragoon trained as a mounted infantryman,

premature discharge, or communication of fire from

The author once tried an even more severe test, loading a Colt .56 revolving rifle cylinder with full charges

After the trial, Colt adjourned with Secretary of War

In and , Colt produced a slight surplus of

spite of the state militia anxiety, the competition of

No. 6144 has a number only on the frame, other

No. 12120 is a Government pistol, 4-screw, 8-inch

No. 17678 over “o”, once was fitted with a stock,

No. 17704 over “o” (an actual “o”, not a zero as in

Thenceforth the regular New Model Army had an

highly of in Jeff Davis’ tenure as War Secretary, to

First and foremost a cavalryman’s pistol, the New

noted:

The price was the old price fixed in Walker Colt

, so the comparison is not out of line. There are

The requisitions from the field were piling up, and

Between these and a purchase in March, ,

a final dispatch of 500 NMA’s to Peter Williams & Co.

300 New Model Army shipped December 27, to Georgia

Sage of Charleston,

160 “ “ “ “ (with 80 stocks) January 17,

William T. Martin,

BSKBSSEgX,

CARTRIDGES,

REVOLVING SHOT GUN,

120

1100

500

(prior to April 16, ) H. D.

Norton & Brother,

Williams & Company,

A total of 2230 New Model Armys shipped up to

More may have been so shipped, while numerous

In a petition to Congress, during consideration of

But it was one of the early Colts that brought about

When Ripley ordered that the 5,000 pistols undergo

Parsons has made an estimate of total New Model

, engraved “To Lieut. Nelson U. S. Navy from

A hiatus in New Model deliveries occurred after

32,500 “dragoon pistols” had been delivered to Ordnance by April 15, . Thereafter the works force

, exactly 9,900 of the .58 rifles had been okayed

June 6, , Root altered the model omitting the

On June 6, Root and Ripley signed a contract for

When Sam Colt died, the local poet laureate and

him we lose today, we may not see again.” She was to

The succeeding contract for the first time specifies

The creeping lever was designed by Elisha Root in

The lever as fitted to the Army had six studs which

pressed hard into the steel barrel and sometimes raised

The Army weighing two pounds 11 ounces was

Some time late in or early Colt had several experimental Dragoon revolvers made up. Their

subject of his biography, General Wade Hampton,

According to Glenn E. Davis, quoted in Butler And

The Navy frame from the .36 belt pistol was selected

This pistol was marked “M” on barrel, frame, and

On pistol “M,” Nos. 37, and 78, the small Navy

Colt’s endorsement on this letter set factory policy

The long handle frame appears to have been pioneered on the hinged lever New Model pistols; at least,

The Dragoon trained as a mounted infantryman,

premature discharge, or communication of fire from

The author once tried an even more severe test, loading a Colt .56 revolving rifle cylinder with full charges

“There are a few minor points requiring modification,We think these minor points requiring modificationto which the manufacturer’s notice has been called, and to which he should be required to attend in any arms he may furnish for the Government use. With these modifications, the Board are satisfied that the New Model Revolver, with the 8-inch barrel, will make the most superior cavalry arm we have ever had, and they recommend the adoption of this New Model, and its issue to all the mounted troops.”

After the trial, Colt adjourned with Secretary of War

I shall send to Col. May a specimen of this new arm soThese improvements seem to include: fitting foursoon as it can possibly be got ready, that he may learn the changes which have been made which you so highly approve, which I hope will reach him for trial by the Mounted Men of the frontier before his official report is made to you.

I shall have the perfected model embracing the suggestionsmade by the board officers & approved by you ready in a very short time, & will send or bring it to you for your approval to govern me in manufacturing to meet the wants of Government.

In and , Colt produced a slight surplus of

spite of the state militia anxiety, the competition of

about 3-9/16 inches in length with dash terminals.

No. 3712 is a fluted cylinder gun, lightly scroll engraved, and suspect as it has a 3-screw frame. The No. 6144 has a number only on the frame, other

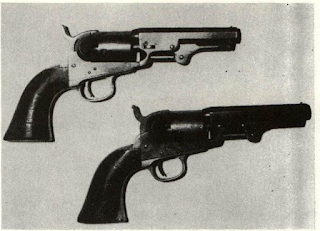

No. 12120 is a Government pistol, 4-screw, 8-inch

No. 17678 over “o”, once was fitted with a stock,

No. 17704 over “o” (an actual “o”, not a zero as in

Thenceforth the regular New Model Army had an

|

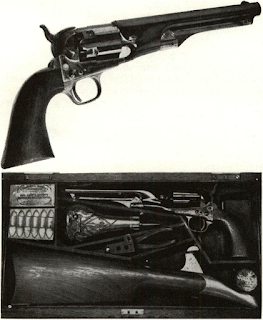

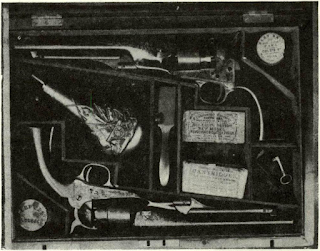

| Regular New Model Army shown is G.I. with inspection |

First and foremost a cavalryman’s pistol, the New

noted:

The trooper having been well instructed in the manual onRegular deliveries of the New Model Army to thefoot, should be made to repeat it mounted, first at a halt and afterwards at the different gaits, but the progress of instruction should be slow. Every trooper should be made to execute all the motions well (i.e., loading and firing) at each gait before passing to a more rapid gait.

Aiming, and especially at right gaits, requires some remark.Aiming should be practiced to the right, left, front, and rear. In aiming to the right, left, or front at a gallop, or at speed, the trooper should rise a little in the stirrups and incline the body a little to the front; the arm should be half extended, and the body turned in the direction of the object aimed at. In aiming to the rear, the right shoulder should be well thrown back and the right arm extended to its full length.

Firing should, at first, be executed with the greatest careand deliberation. The target should be 8 feet high and 3 feet wide, with a vertical and horizontal line, each an inch wide, intersecting at the height of five feet. The vertical line should pass through the center of the target. The troopers should be formed in front of, facing, and at a distance of 100 paces from the target. The firing should, at first, be executed at a distance of ten paces, but the distance should be gradually increased to 40 paces. A peg in front of the target will mark the point from which the trooper is to fire.

To commence firing, the instructor will cause the trooperon the right to move five paces to the front, turn to the right, move 30 paces to the front, turn to the left, move to the front until he arrives abreast of the peg in front of the target, turn towards it, cock the pistol, aim and fire deliberately; then turn to the left, move 30 paces to the front, turn to the left again, and pass to the rear of the troop, reload and take his place on the left of the rank.

To fire to the right the trooper executes what he did infiring to the front, except that he does not turn towards the target when he comes in front of it. To fire to the left the instructor causes the trooper on the left to execute, inversely, what the trooper on the right executed in firing to the right. To fire to the rear, the trooper on the right executes what he did in firing to the front, except that he turned from the target instead of towards it, and aims to the rear. The points where the troopers are required to turn in the exercise will be marked by pegs.

At first but one chamber of the pistol should be discharged

by each trooper, and great care should be taken to guardagainst frightening the horses. The troopers should be cautioned to be gentle with them, and soothe them when excited. When a young horse is very timid, he should be accompanied by one which has courage. When the troopers are sufficiently instructed in the exercise, and control their horses well, three or more targets should be used. They should at first be placed on the same line, and 100 paces apart; but the distance should be gradually reduced to 50 paces.

The price was the old price fixed in Walker Colt

, so the comparison is not out of line. There are

The requisitions from the field were piling up, and

Between these and a purchase in March, ,

a final dispatch of 500 NMA’s to Peter Williams & Co.

300 New Model Army shipped December 27, to Georgia

Sage of Charleston,

160 “ “ “ “ (with 80 stocks) January 17,

William T. Martin,

BSKBSSEgX,

CARTRIDGES,

REVOLVING SHOT GUN,

120

1100

500

(prior to April 16, ) H. D.

Norton & Brother,

Williams & Company,

A total of 2230 New Model Armys shipped up to

More may have been so shipped, while numerous

In a petition to Congress, during consideration of

But it was one of the early Colts that brought about

When Ripley ordered that the 5,000 pistols undergo

Parsons has made an estimate of total New Model

, engraved “To Lieut. Nelson U. S. Navy from

A hiatus in New Model deliveries occurred after

32,500 “dragoon pistols” had been delivered to Ordnance by April 15, . Thereafter the works force

, exactly 9,900 of the .58 rifles had been okayed

June 6, , Root altered the model omitting the

On June 6, Root and Ripley signed a contract for

When Sam Colt died, the local poet laureate and

him we lose today, we may not see again.” She was to

The succeeding contract for the first time specifies

Office of Inspector of Contract Arms

Very respectfully, your obedient servant,

P. V. Hagner

These 155 pistols at the special price of $13.73, 52^

Comments

Post a Comment